Design and Build

Construction System

Light Gauge Steel (LGS), Insulation & Materials

Core structure made of Light Gauge Steel (LGS) lightweight, precise, durable, and resistant to corrosion, moisture, and pests.

Structural lifespan estimated at over +100 years.

Fully compatible with a wide range of cladding and exterior finish systems.

Excellent thermal and acoustic insulation using closed-cell PU spray foam

(R19–R21) and rock wool.Moisture-resistant MGO or gypsum boards for wet areas and internal partitions.

Custom-designed doors, windows, and finishings based on project design.

Materials selected for energy efficiency, lightweight construction, and sustainability.

Step-by-Step Manufacturing Process

1. Conceptual design and technical drawings, including structure, MEP, interior design, and finishes.

2. Factory setup and resource allocation, with dedicated production teams and material sourcing.

3. Structural manufacturing: LGS frame, walls, ceilings, insulation, windows, and doors.

4. Installation of systems: electrical, HVAC, plumbing, and fire safety.

5. Interior fit-out and bespoke finishes as per client specifications.

6. Final quality checks, testing, and shipping preparation.

Certain elements are completed on site, including utility connections, ramps, loose furniture, and commissioning.

Timelines, Quality & Sustainability

The stimated timeline per module is 10 weeks from final design approval.

Up to 60% faster than traditional construction.

Strict quality control throughout design, manufacturing, assembly, and delivery.

Optimized international shipping, including sea and rail transport.

Sustainable approach:

Up to 60% fewer lifecycle emissions

Up to 66% material savings

40% lower primary energy consumption

In-House Production & Strategic Partnerships

Production takes place in certified, high-precision factories.

All technical and project teams coordinated directly from Dubai.

Strategic collaborations with local and international partners for transport, assembly, and finishings.

System adaptable to building regulations across USA, EU, MENA, Australia, and Southeast Asia.

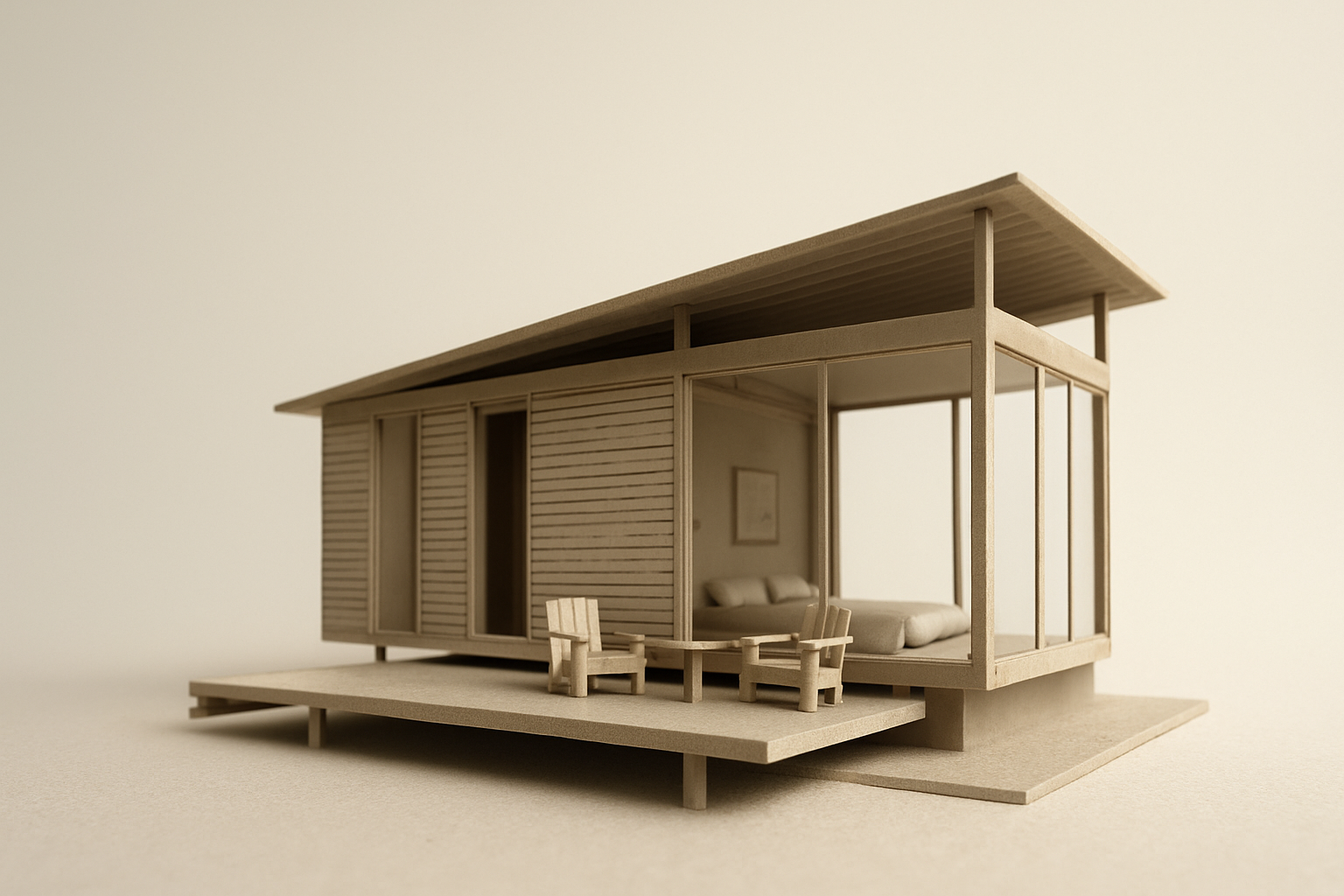

alterdomus module AD-O1

Frequently Asked Questions

-

Each module takes approximately 10 weeks to manufacture after the final design approval. This timeline can be optimized for larger orders thanks to our streamlined industrial production process. International delivery is coordinated directly from Dubai, managing both land and sea transport based on your project’s location.

-

Absolutely. At Alterdomus, we offer a fully bespoke approach. We tailor the layout, materials, finishes, façade, and interior fittings to your specific needs and the unique context of your site. Our design team works closely with you to ensure every detail reflects your vision.

-

Our modules are built using Light Gauge Steel (LGS) a strong, lightweight, and highly durable structural system. We apply closed-cell PU spray foam (R19–R21) and acoustic rockwool to ensure outstanding thermal and acoustic insulation, providing year-round comfort in both cold and warm climates.

-

Yes. Our system is fully adaptable to meet building codes and regulatory requirements in multiple regions, including the EU, USA, MENA, Australia, and Southeast Asia. We work with local engineers and consultants to ensure full compliance at every stage — from structural engineering to MEP and fire safety systems.

-

Yes. We offer turnkey delivery, which includes transport, on-site installation, and final commissioning. Depending on the project and location, we work with trusted local partners or deploy our own team to ensure proper assembly and connection of all systems, guaranteeing full operational readiness.